Why you should change the oil ATF in automatic transmissions

Theory versus reality

Many owners of cars equipped with automatic transmissions hesitate and delay changing the oil in the gearbox. Opinions on this subject are very divergent. In addition, many car manufacturers do not provide a schedule for oil changes in automatic transmissions when performing standard periodic inspections. However, attention should be paid to the fact that car manufacturers do not prohibit or advise against changing the oil, but only do not provide for it during the standard service procedure. By design, the automatic transmission must maintain efficiency and enable trouble-free operation during the warranty period of the vehicle. In order to ensure trouble-free operation over a longer period of time, well after the warranty period, the automatic transmission should be properly taken care of. According to the principle "prevention is better than cure", preventative measures are recommended. The service practice clearly shows that automatic gearboxes, without maintenance operating at distances over 200,000 km is when the first signs of wear, tearing or stalling of gears will appear, and the unit usually requires an overhaul, as an oil change alone is usually not able to return the gearbox to trouble-free operation. In order to unambiguously deal with the myths about this topic, you should start from the beginning and present the oils used in terms of the principle of operation of automatic transmissions.

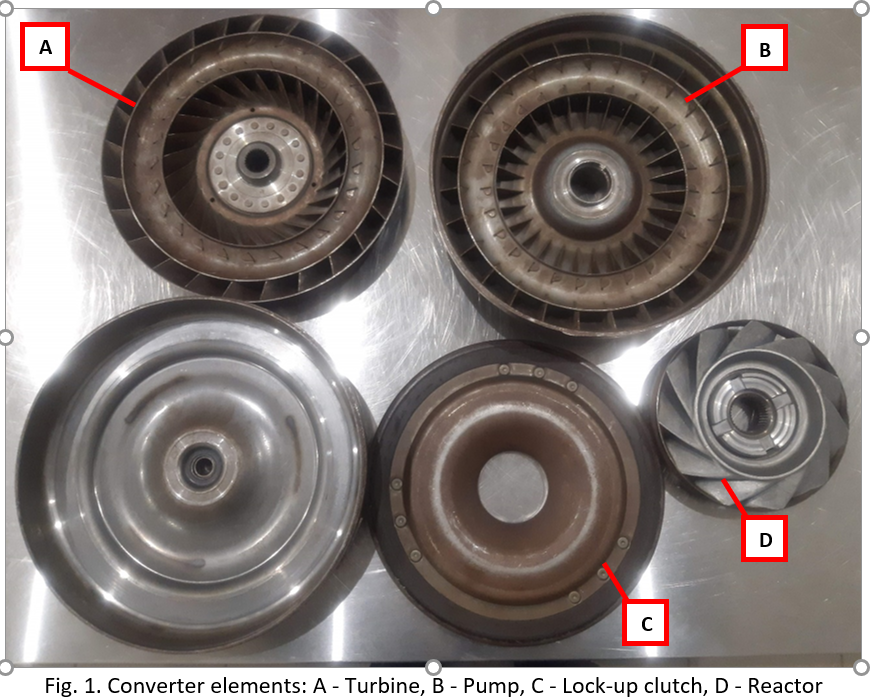

The converter also has a Reactor (Fig. 1 - D) with a bearing with a one-way clutch. Temperature transfer properties, proper coefficient of friction and lubricating properties are crucial for its proper operation. In service practice, the clutch is often broken, as a result of which the car accelerates very slowly, not responding dynamically to pressing the accelerator pedal.

Set of friction plates and clutch spacers

Piston for the hydraulic control module

Automatic gearbox planetary gear unit